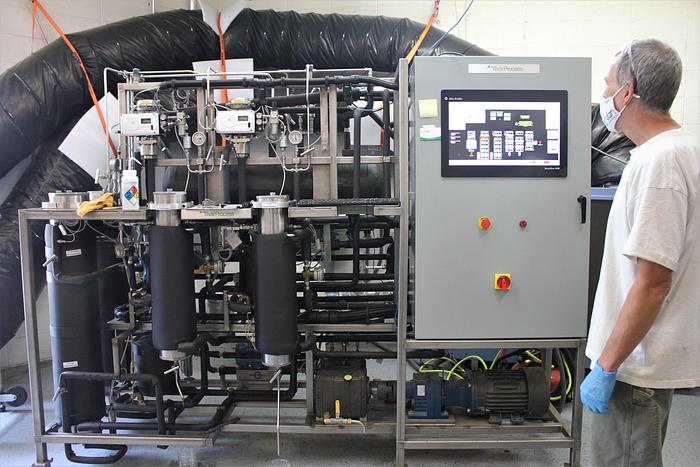

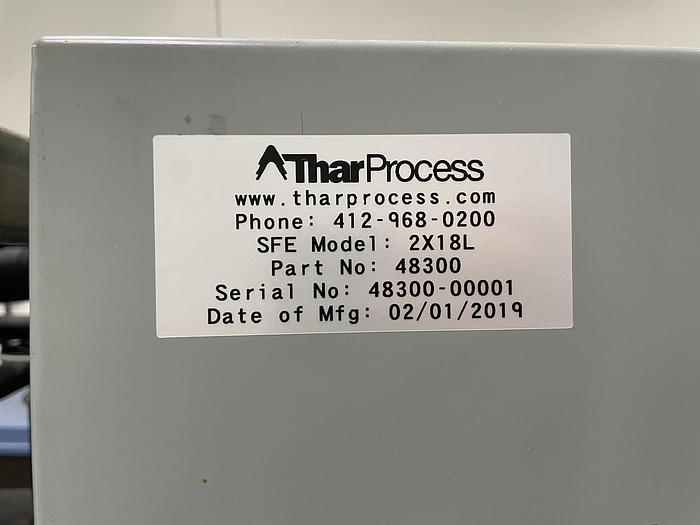

Supercritical CO2 from Thar Process SuperFastTM 2x18L + Heater and Chiller

Sold

Supercritical CO2 from Thar Process SuperFastTM 2x18L + Heater and Chiller

$60,000 (USD)

Location:Longmont, CO

Description

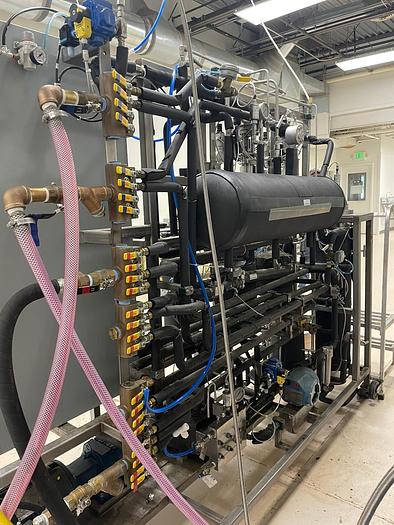

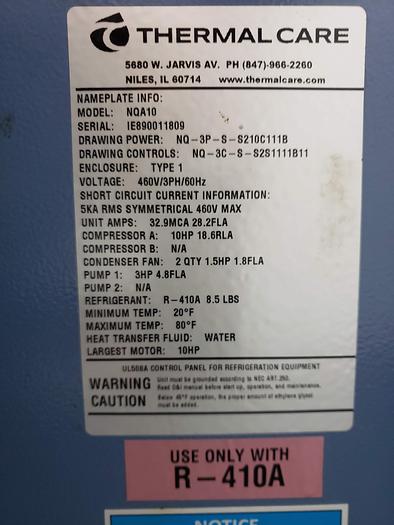

Gently used CO2 extractor from Thar Process. Comes with heater/temp control system from MicroTherm, and a chiller from ThermalCare. Other specifications as follows:

Extraction Vessels: 2x18L Extraction Vessels

- Design pressure: 5,000 psi (345 bar)

- Design temp: 80°C

- Max. operating pressure: 4,350 psi (300 bar)

- Max. operating temp: 20-60 °C

- Jacket Type: Tube Coil

- Heat Exchanger: Designed for heating mode

- Split Baskets are custom designed for high-efficiency fluidization for optimal extraction and near-zero gradient

- Basket Payload Volume: 15L

- Hoist provided for ease of basket access and manipulation

Maximum operating conditions may vary based on process characteristics.

Collection vessels: 2 x 7.5L Separators

- Design pressure: 2,500 psi (172 bar)

- Design temp: 80°C

- Max. Operating Pressure: 2,175 psi (150 bar) Medium Pressure

870 psi (60 bar) Low Pressure

- Jacket Type: Tube Coil

- MP Heat Exchanger: Designed for heating mode

- LP Heat Exchanger: Designed for heating mode

Recirculation System: 1x 40L Receiver

- Design pressure: 1,200 psi (82 bar)

- Design temp: 80°C

- Max. Operating Pressure: 870 psi (60 bar)

- Maximum CO2 flow rate: 2.5 kg/min

- Heat Exchanger(s): Condensing and sub-cooling for receiver pressure

control and pump flow

- All pressure vessels are designed in accordance with ASME Section VIII, Div. 1

- All pressure vessels are installed with ASME “UD” stamped rupture discs

Material of Construction:

- Process Equipment & Piping: Stainless Steel

- Equipment Skids: Stainless Steel

- Utility Piping: Stainless Steel/Brass

- Control Panel: Powder Coated Galvanized Steel

Control Specifications:

- Allen-Bradley Compact Logix PLC Controller with Factory Talk HMI frontend

- Windows based HMI providing operator controls for start, stop, pressure, temp, and flow with monitoring features & safety interlocks to prevent over- pressurization

- Data logging & trending

- 24V DC Control Voltage

- All electrical drawings are PE stamped by an independent firm

Spacing Requirements: 7’6” X 2’8” X 6’8” (L x W x H)

- A minimum of 4’ x 8’ (W x H) door opening required to haul the equipment

Specifications

| Manufacturer | Thar Process |

| Model | 2x18L |

| Year | 2019 |

| Condition | Used |