SaintyCo Softgel Encapsulation Line – Gelatin Melting, Mixing, Drying & Bottling – Turnkey System

SaintyCo Softgel Encapsulation Line – Gelatin Melting, Mixing, Drying & Bottling – Turnkey System

$55,000 (USD)

Location:Georgia

or

Call +1 425-358-0425

Description

The SaintyCo Softgel Encapsulation Processing Line is a comprehensive system designed to produce high-quality soft gelatin capsules efficiently. Below is a detailed breakdown of each component in the line:

SaintyCo GMV-100 Gelatin Melting Tank:

- Function: This tank is responsible for melting and mixing gelatin, which is essential for forming the softgel capsule shells.

- Capacity: 100 liters

- Temperature Control: Capable of maintaining temperatures below 100°C

- Power Consumption: 4 kW

- Mixing Speed: Operates at 35 rpm

- Dimensions: 1,100 mm (L) x 650 mm (W) x 1,655 mm (H)

- Weight: Approximately 1,300 kg

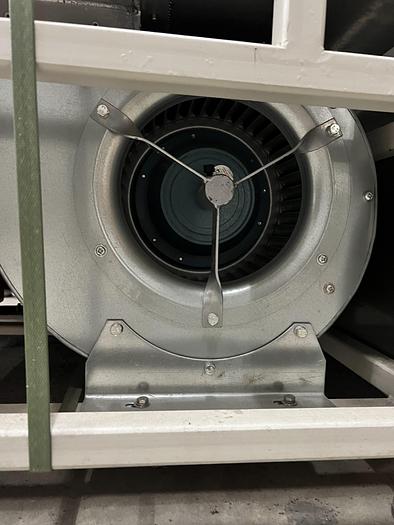

SaintyCo Tumble Dryers (2 dryers, varying screen size to polish caps):

- Function: After encapsulation, these dryers remove excess moisture from the softgel capsules, ensuring uniform drying and preventing defects

- Quantity: Typically supplied in pairs

- Tumbler Size: Diameter of 316 mm and length of 417 mm

- Power Supply: 380 V, 50 Hz, 3-phase

- Dimensions: 1,400 mm (L) x 450 mm (W) x 800 mm (H) per unit.

- Weight: Approximately 90 kg per unit.

SaintyCo MST-100 Material Mixing Tank:

- Function: Designed for mixing various ingredients to prepare the fill material for the softgel capsules.

- Capacity: 100 liters

- Temperature Control: Maintains product temperatures below 100°C

- Power Consumption: 4 kW heating element with a 0.75 kW mixing motor

- Mixing Speed: Operates at 35 rpm

- Dimensions: 1,100 mm (L) x 650 mm (W) x 1,655 mm (H)

- Weight: Approximately 1,300 kg

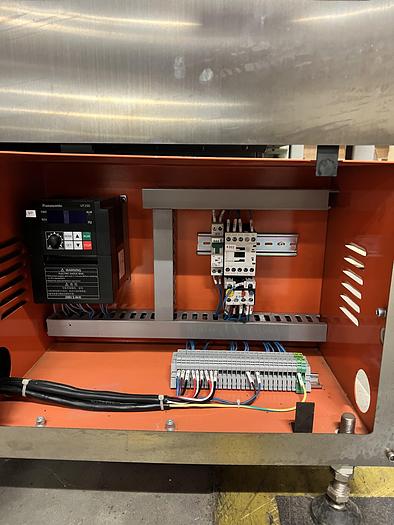

Automatic Airjet Cleaning Machine with Bottling Capabilities:

- Function: This machine cleans bottles using compressed air jets and a suction blower, ensuring they are free from contaminants before filling. It also offers bottling capabilities, streamlining the packaging process. multipackmachinery.com

- Speed: Capable of cleaning up to 200 bottles per minute, depending on bottle size. Attachment included with capability to house 6 different bottle sizes

- Bottle Diameter Compatibility: Handles bottles up to 65 mm in diameter

- Power Requirements: Operates on 415 VAC, three-phase power supply (50 Hz) and 220 VAC, single-phase power supply

- Compressed Air Requirement: Filtered air at 6 to 10 Bar, provided by the customer

- Conveyor Height: Adjustable between 750 mm and 840 mm

- Overall Dimensions: 3,000 mm (L) x 850 mm (W) x 1,225 mm (H)

This integrated processing line ensures a seamless workflow from gelatin preparation to capsule drying and final cleaning and bottling, optimizing efficiency and product quality in softgel production.

Specifications

| Manufacturer | SanityCo |

| Model | SG50, GMV-100, Tumble Dryer, MST-100, SBAJC-100 |

| Year | 2019 |

| Condition | Used |

| Stock Number | 00057 |